ASTM F3124-15

(Practice)Standard Practice for Produce Heat Butt Fusion Joints in Plastic Piping Systems or Fittings

Standard Practice for Produce Heat Butt Fusion Joints in Plastic Piping Systems or Fittings

SIGNIFICANCE AND USE

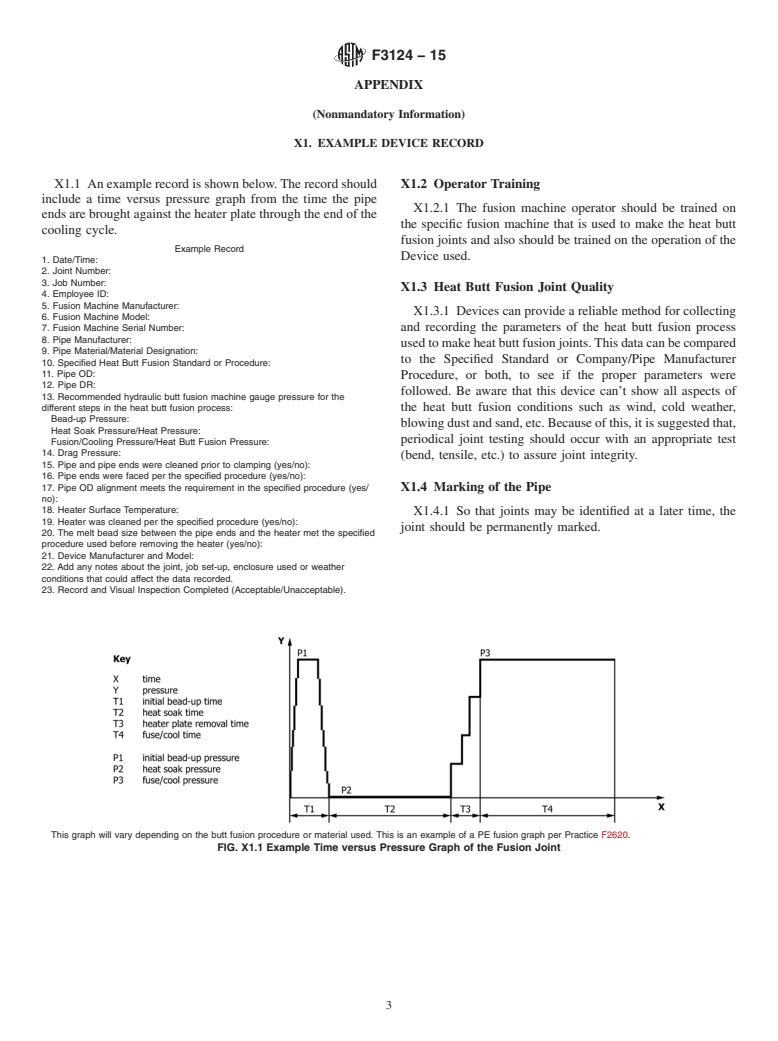

5.1 The Device record includes information about how the heat butt fusion joint was made (heater temperature, pressures and times for the heating, fusion and cooling steps) and other important information about the process, job, equipment used, etc. The Device record is compared to the specified heat butt fusion procedure parameters to determine if the procedure was followed correctly. For comparison purposes, a graph of time versus pressure is generated from the data record to show pressure changes that occur during the butt fusion process. Comparing the time versus pressure graph to the steps in the procedure helps determine that the procedure parameters were observed. (See Appendix X1.) These records may be downloaded from the device and stored.

SCOPE

1.1 This practice specifies the data recording information that is recorded, when data recording equipment is used, on butt fusion joints in a plastic piping system in order to compare the procedure used in making the joint to the heat butt fusion joining procedure specified. This practice is suitable for use with all heat butt fusion joining procedures that require measurable time and pressure profiles, such as Practice F2620, Specification F2785, Specification F2945 international standards or other qualified procedures. This practice applies to hydraulically operated heat butt fusion machines only and does not apply to manually operated fusion machines or specialized fabrication equipment for fittings in a controlled environment with proprietary procedures and processes.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3124 − 15

StandardPractice for

Produce Heat Butt Fusion Joints in Plastic Piping Systems

1

or Fittings

This standard is issued under the fixed designation F3124; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope microprocessor, internal memory for data storage, and connec-

tions for pressure sensors to the hydraulic fusion machine.

1.1 This practice specifies the data recording information

Devices may interface with a personal computer and may

that is recorded, when data recording equipment is used, on

utilize software to activate the Device and to view and analyze

butt fusion joints in a plastic piping system in order to compare

the collected data. Other Devices may have a local interface

the procedure used in making the joint to the heat butt fusion

device, such as a keypad or touch sensing, LCD display, and

joining procedure specified. This practice is suitable for use

can be used as a standalone device.

with all heat butt fusion joining procedures that require

measurable time and pressure profiles, such as Practice F2620,

4. Summary of Practice

Specification F2785, Specification F2945 international stan-

4.1 The principle of heat butt fusion of plastic pipe is to

dards or other qualified procedures. This practice applies to

apply heat, at a designated temperature, to two prepared pipe

hydraulically operated heat butt fusion machines only and does

ends for a heat soak period and then fuse them together by the

not apply to manually operated fusion machines or specialized

application of a sufficient force, thereby resulting in fusion.

fabrication equipment for fittings in a controlled environment

This practice identifies the information that is collected by the

with proprietary procedures and processes.

data recording device about the heat butt fusion joint. The

1.2 This standard does not purport to address all of the

Device records the hydraulic pressures and times during the

safety concerns, if any, associated with its use. It is the

butt fusion process for individual joints and manual entries

responsibility of the user of this standard to establish appro-

such as operator identification, product information, fusion

priate safety and health practices and determine the applica-

parameters, and heater surface temperature.

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents

5.1 The Device record includes information about how the

2.1 ASTM Standards:

heat butt fusion joint was made (heater temperature, pressures

F2620 Practice for Heat Fusion Joining of Polyethylene Pipe

and times for the heating, fusion and cooling steps) and other

and Fittings

important information about the process, job, equipment used,

F2785 Specification for Polyamide 12 Gas Pressure Pipe,

etc. The Device record is compared to the specified heat butt

Tubing, and Fittings

fusion procedure parameters to determine if the procedure was

F2945 Specification for Polyamide 11 Gas Pressure Pipe,

followed correctly. For comparison purposes, a graph of time

Tubing, and Fittings

versus pressure is generated from the data record to show

pressure changes that occur during the butt fusion process.

3. Terminology

Comparing the time versus pressure graph to the steps in the

3.1 Definitions:

procedure helps determine that the procedure parameters were

3.1.1 Data Recording Device (“Device”)—This is an instru-

observed. (See Appendix X1.) These records may be down-

ment that obtains and stores information.

loaded from the device and stored.

3.1.1.1 Discussion—This is generally an electronic device

that accepts sensor input for pressure and time and manual 6. Apparatus—General Requirements

input for other information. These Devices are typically small,

6.1 Data Recording Device:

battery powered, portable, and equipped with a

6.1.1 The Device shall be capable of collecting the follow-

ing information:

1

the heater temperature at the beginning of the heat cycle and the pressures

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

applied during the heating, fusing and cooling cycle

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

time for each stage of the process from the beginning of the heat cycle

Current edition approved March 1, 2015. Published March 2015. DOI: 10.1520/

through the end of the cool cycle

F3124–15

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3124 − 15

7. Procedure

the operators name or identi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.