ASTM E3299/E3299M-22

(Test Method)Standard Test Methods for Compression Resistance of Helmets

Standard Test Methods for Compression Resistance of Helmets

SIGNIFICANCE AND USE

4.1 The purpose of this standard is to provide reliable and repeatable compression test methods for the evaluation of helmets used in law enforcement, corrections, and military applications.

4.2 It is anticipated that this standard will be referenced by certifiers, purchasers, or other users in order to meet their specific needs. Those users will specify which test methods apply and will specify any performance categories or levels.

SCOPE

1.1 This standard provides test methods for assessing compression resistance of helmets worn by military, law enforcement, and corrections personnel. These test methods are applicable for many styles of helmet (that is, high-cut, mid-cut, full-cut).

1.2 Three compression test methods are included: (1) top-to-bottom, (2) side-to-side, and (3) front-to-back.

1.3 It is anticipated that this standard will be referenced by suppliers, certifiers, purchasers, or other users to meet their specific needs. Those users will specify, in other standards and specifications, which test methods and conditioning procedures are applicable and will specify any performance categories or levels.

1.4 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3299/E3299M − 22

Standard Test Methods for

1

Compression Resistance of Helmets

ThisstandardisissuedunderthefixeddesignationE3299/E3299M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This standard provides test methods for assessing com-

pression resistance of helmets worn by military, law D2240 Test Method for Rubber Property—Durometer Hard-

ness

enforcement,andcorrectionspersonnel.Thesetestmethodsare

applicable for many styles of helmet (that is, high-cut, mid-cut, D3575 Test Methods for Flexible Cellular Materials Made

from Olefin Polymers

full-cut).

D4819 Specification for Flexible Cellular Materials Made

1.2 Three compression test methods are included: (1) top-

From Polyolefin Plastics

to-bottom, (2) side-to-side, and (3) front-to-back.

E3005 Terminology for Body Armor

1.3 It is anticipated that this standard will be referenced by

F1446 Test Methods for Equipment and Procedures Used in

suppliers, certifiers, purchasers, or other users to meet their

Evaluating the Performance Characteristics of Protective

specific needs. Those users will specify, in other standards and

Headgear

specifications,whichtestmethodsandconditioningprocedures

2.2 U.S. Government Standards:

are applicable and will specify any performance categories or

FMVSS No. 218 Laboratory Test Procedure for Motorcycle

levels.

Helmets, National Highway Traffic Safety Administra-

3

tion

1.4 Units—The values stated in either SI units or inch-

2.3 ISO/IEC Standards:

pound units are to be regarded separately as standard. The

ISO/IEC 17025 General Requirements for the Competence

values stated in each system are not necessarily exact equiva-

4

of Testing and Calibration Laboratories

lents; therefore, to ensure conformance with the standard, each

system shall be used independently of the other, and values

3. Terminology

from the two systems shall not be combined.

3.1 Definitions:

1.5 This standard does not purport to address all of the

3.1.1 basic plane, n—an anatomical plane (Frankfort hori-

safety concerns, if any, associated with its use. It is the

zontal plane) that includes the superior rim of the external

responsibility of the user of this standard to establish appro-

auditory meatus (upper edge of the external openings of the

priate safety, health, and environmental practices and deter-

ear) and the inferior margin of the orbit (the lowest point of the

mine the applicability of regulatory limitations prior to use.

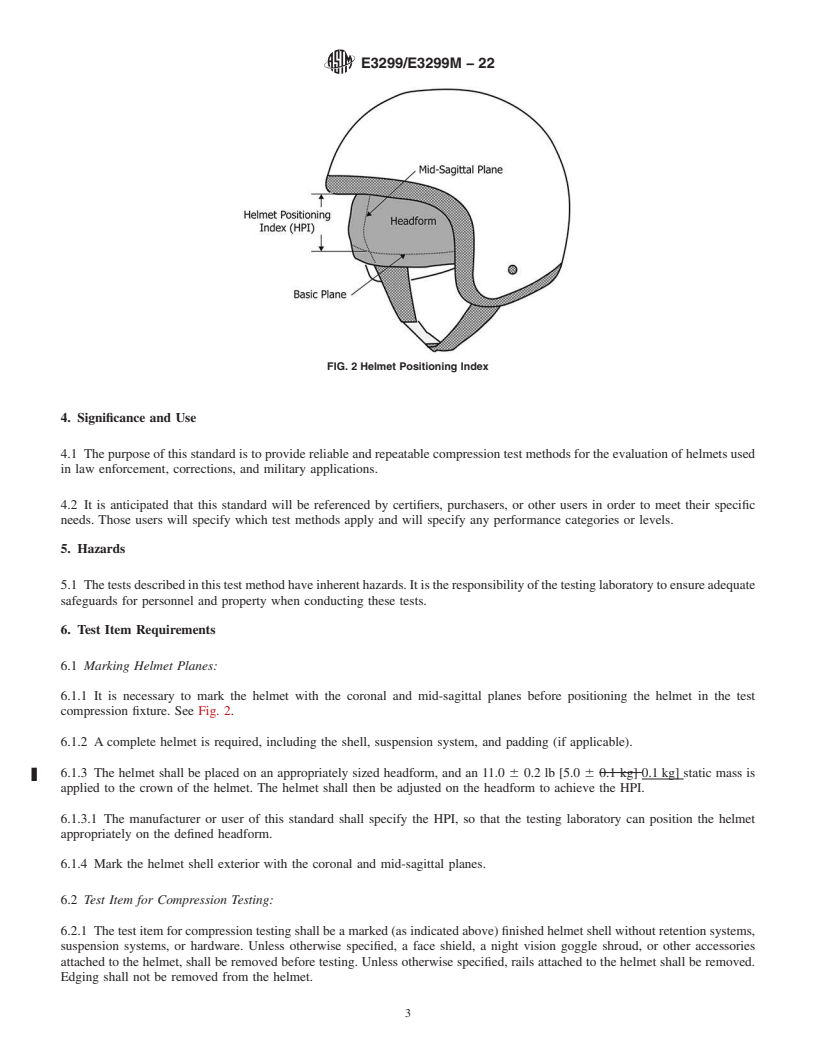

floor of the eye socket) (see Fig. 1 and Fig. 2).

1.6 This international standard was developed in accor-

(Test Method F1446)

dance with internationally recognized principles on standard-

3.1.2 controlled ambient, n—conditions with temperature of

ization established in the Decision on Principles for the

68 6 10 °F [20.0 6 5.6 °C] and 50 6 20 % relative humidity

Development of International Standards, Guides and Recom-

(RH). (Adapted from Terminology E3005)

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

These test methods are under the jurisdiction of ASTM Committee E54 on the ASTM website.

3

Homeland Security Applications and are the direct responsibility of Subcommittee Available from National Highway Traffic Safety Administration (NHTSA),

E54.04 on Personal Protective Equipment (PPE). 1200 New Jersey Ave., SE, Washington, DC 20590, http://www.nhtsa.gov.

4

Current edition approved March 1, 2022. Published March 2022. Originally Available from International Organization for Standardization (ISO), ISO

approved in 2021. Last previous edition approved in 2021 as E3299/E3299M – 21a. Central Secretariat, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Geneva,

DOI: 10.1520/E3299_E3299M-22. Switzerland, https://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3299/E3299M − 22

shall specify the size of the headform and the vertical distance

(Test Method F1446); see Fig. 2. (U.S. DOT FMVSS No. 218)

3.1.5 mid-sagittal plane, n—an anatomical plane perpen-

dicular to the basic plane and containing the midpoint of the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E3299/E3299M − 21a E3299/E3299M − 22

Standard Test Methods for

1

Compression Resistance of Helmets

This standard is issued under the fixed designation E3299/E3299M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard provides test methods for assessing compression resistance of helmets worn by military, law enforcement, and

corrections personnel. These test methods are applicable for many styles of helmet (that is, high-cut, mid-cut, full-cut).

1.2 Three compression test methods are included: (1) top-to-bottom, (2) side-to-side, and (3) front-to-back.

1.3 It is anticipated that this standard will be referenced by suppliers, certifiers, purchasers, or other users to meet their specific

needs. Those users will specify, in other standards and specifications, which test methods and conditioning procedures are

applicable and will specify any performance categories or levels.

1.4 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in

each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other, and values from the two systems shall not be combined.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D2240 Test Method for Rubber Property—Durometer Hardness

D3575 Test Methods for Flexible Cellular Materials Made from Olefin Polymers

D4819 Specification for Flexible Cellular Materials Made From Polyolefin Plastics

E3005 Terminology for Body Armor

F1446 Test Methods for Equipment and Procedures Used in Evaluating the Performance Characteristics of Protective Headgear

2.2 U.S. Government Standards:

3

FMVSS No. 218 Laboratory Test Procedure for Motorcycle Helmets, National Highway Traffic Safety Administration

1

These test methods are under the jurisdiction of ASTM Committee E54 on Homeland Security Applications and are the direct responsibility of Subcommittee E54.04

on Personal Protective Equipment (PPE).

Current edition approved Dec. 1, 2021March 1, 2022. Published December 2021March 2022. Originally approved in 2021. Last previous edition approved in 2021 as

E3299/E3299M – 21.E3299/E3299M – 21a. DOI: 10.1520/E3299_E3299M-21A.10.1520/E3299_E3299M-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from National Highway Traffic Safety Administration (NHTSA), 1200 New Jersey Ave., SE, Washington, DC 20590, http://www.nhtsa.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3299/E3299M − 22

2.3 ISO/IEC Standards:

4

ISO/IEC 17025 General Requirements for the Competence of Testing and Calibration Laboratories

3. Terminology

3.1 Definitions:

3.1.1 basic plane, n—an anatomical plane (Frankfort horizontal plane) that includes the superior rim of the external auditory

meatus (upper edge of the external openings of the ear) and the inferior margin of the orbit (the lowest point of the floor of the

eye socket) (see Fig. 1 and Fig. 2).

(Test Method F1446)

3.1.2 controlled ambient, n—conditions with temperature of 68 6 10°F10 °F [20.0 6 5.6°C]5.6 °C] and 50 6 20 % relative

humidity (RH). (Adapted from Terminology E3005)

3.1.3 coronal plane, n—an anatomical plane perpendicular to both the basic and midsagittal planes and passing through the

superior rims of the right and left auditory meatuses; the transverse plane

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.